|

Vmax

starter Clutch

Project

chronology:

....2004Oct...Page started, left in draft form.

....2006Jan....iowaz Vmax pages were deleted from the web host.

....2010Mar....The old starter clutch page/project was

uploaded in draft form for a Vmax contact that needed info.

Remember: All data & links are old & likely void.

....A sequence of pictures of the starter clutch

removal and PCW Racing's 'fix' is located in this photo album (I used both PCW

Racing's puller & his 'fix).

http://public.fotki.com/iowaz/iowaz-cycles/vmax-starter-clutch/

....Do Google, YouTube,

Facebook searches for new information.

Iowaz Index Page

Iowaz Photo

Hosting Site

Vmax T-boost kit

Damaged starter clutch.

Worn threads on fasteners, worn/cracked plate, worn rollers, weak

springs.

General Overview:

How does the Starter Clutch work??

....The Starter Clutch is

the mechanism by which the Starter Motor engages and turns over the

Engine for starting.

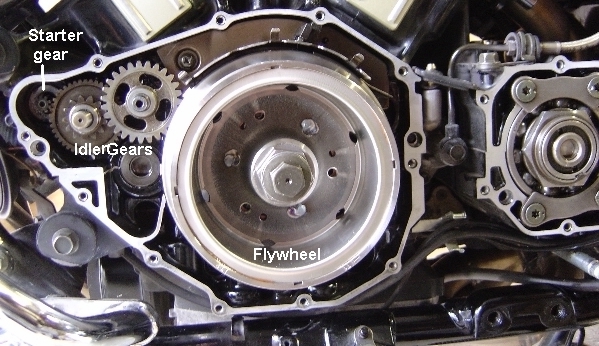

....The Starter Gear is connected to the shaft of

the electric Starter Motor, which through a series of Idler Gears, spins

the large diameter Starter Clutch Gear that lies behind the flywheel.

....The spinning Starter Clutch Gear's center engages and lodges three

rollers/dogs in the Starter Clutch Assembly that is physically connected

to the Flywheel, which in turn is connected to the engine Crank Shaft.

....Through this mechanism the engine is turned over and is started.

The

'health' of the Electrical System and Battery, Starter Motor and Starter Clutch are

important to quick and reliable starting of the Engine.

Where is the Starter Clutch??

....The

Starter Clutch Gear and Assembly lies behind the Flywheel which is behind

the Alternator Cover on the left side of the Vmax.

....The Flywheel must

be removed to get at the Starter Clutch Assembly and Gear. The

removal of the Flywheel from the tapered end of the Crankshaft is often

very, very difficult without the correct Gear Puller and tools.

What has to mechanically be done

to get at the Starter Clutch

Assembly and Gear??

1. The

process starts with removing the left Foot Peg and then the Shifting

Lever.

From this point the sequence of

pictures on the photo site will be helpful to visualize the process.

http://public.fotki.com/iowaz/iowaz-cycles/vmax-starter-clutch/

Next steps

2. Next the Middle Gear Cover is removed (black circular cover

behind the foot peg).

....This will allow for the wires coming from the

Stator of the Alternator to be released from their clips behind the Middle

Gear Cover, so that the Alternator Cover can be set on a box/stand near the rear

tire and out of the way, thus no further removal of the Stator and

Alternator Cover wires are necessary (as described in the manual).

3. The Alternator cover, with its internally attached Stator

Coils, is removed and set off to the rear on a box.

....Info on

how the electrical production and charging system works---the internal

ring of the Flywheel is magnetized, the copper Stator coils sit inside

the Flywheel center and the spinning, the magnetized Flywheel sets up

electron flow down the copper wires toward the electrical system of the

bike, thus this arrangement is the Alternator supplying current to run the

bike and keep the battery charged.

4. At this time it is possible to slip the Idler Gears and

their Shafts off/out to get them out of the way when the Flywheel releases.

....Note: Remember the sequence in the photo album will help

visualize the process?

http://public.fotki.com/iowaz/iowaz-cycles/vmax-starter-clutch/

5. The center bolt holding the Flywheel to the Crank is

removed.

....Suggestion: this bolt can take a lot of force to

break loose. Use a good six point 1/2 inch drive socket (not

twelve point socket, as they often slip on the fastener head, causing

damage), and the longest/strongest breaker bar you can get. If you

do not know what a breaker bar is, surf a tool site such as Sears, or

browse a good tool store. Breaker bars are very necessary in any

tool chest.

6. To remove the flywheel, it is best to then use a gear puller adapted to the removal

of the Vmax Flywheel.

....I would suggest using one such as supplied

by PCW Racing, or build one as shown on Thomas's site (links below).

You can also attempt to use a good puller such as supplied by Sears or SnapOn, but will need to then acquire long high strength bolts, as the

stock ones will likely stretch and make the job difficult to impossible.

....There have been many suggestions for the use of heat and

tapping/hammering the flywheel/crank area to assist removal with stock

pullers. I chose to use PCW's puller, with great success, as the

flywheel just gently released. However, it is best to have a good

compressor and air impact wrench to complete the removal.

....The Vmax Flywheel has historically been

very, very difficult to remove without proper equipment and know how.

Even many cycle shops are stumped by the process. The issues will

be addressed a bit further down this page. The puller will attach

in the three threaded holes in the center of the Flywheel.

7. After the Flywheel is off the bike, the three bolts

holding the Starter Clutch Assembly to the Flywheel can be removed.

....The Starter Gear and Starter

Clutch Assembly can than be inspected and replaced.

....The Starter Clutch

Assembly is bolted to the back of the Flywheel by three bolts. which can

be seen showing from the front (outside) of the flywheel before removal.

8. A new Starter Clutch Gear and Starter Clutch Assembly can be installed or another option such as PCW Racing's fix may be

selected.

....Typically the Starter Clutch on a Vmax will become

dysfunctional around 20k +/-5k miles. The three bolts in some

cases may release much earlier, causing noise and clanking in this area

while the bike is running, thus this is the weak link in the starting

system of the Vmax.

....The usual issue is the wearing of

the surface between the rollers/dogs of the starter clutch assembly and

the inner ring of the Starter Clutch Gear, thus there is no 'solid'

connection between the Starter Motor and Engine, so starting is

hesitates, clicks or ceases. The starter clutch assembly can even

lock up on the crank so the starter motor cannot move at all.

9. There may little to no

warning the Starter Clutch is nearing total failure, or one my hear

excessive noise around the Alternator Cover area, or sense hesitation in

the starting process as the dogs fail to grasp the Starter Clutch Gear.

Bottom line, if you run a Vmax very many miles, you are going to have to

repair your Starter Clutch. Apparently the Starter Motor runs for

more mileage and will need to be rebuilt or replaced less often, perhaps

in the 40-80k range.

Above:

Shows what

one will see when the covers are pulled off. The Starter Clutch

Assembly is behind the flywheel. Note the large hex bolt head in the

middle attached the flywheel to the engine crank.

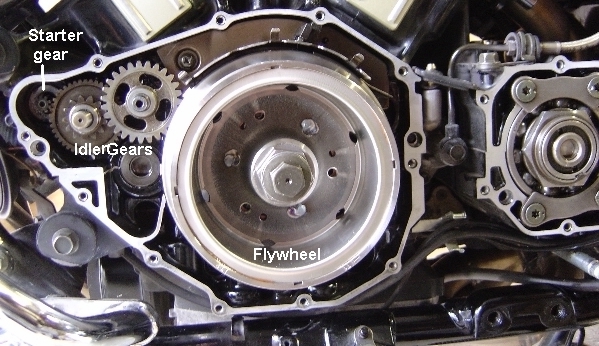

Below: After the

Starter Clutch Assembly was unbolted from the back of the Flywheel, the

Assembly was slipped back on the Crank to slow the relationship between

all of the 'starting' gears' and the Starter Clutch Assembly. The

spinning Starter Clutch Gear engages and lodges the three roller/dogs of

the Starter Clutch Assembly to spin the flywheel/crank/engine for

starting. The main wear causing Starter Clutch failure is the

interface/connection/surface between the inner ring of the Starter Clutch

Gear and the three rollers/dogs of the Starter Clutch Assembly.

Thoughts:

...Beware that the three bolts holding the Starter Clutch Assembly to the

Flywheel can loosen, possibly allowing metal debris to release in area of

the spinning Flywheel and oil supply. Excessive noise under the

Alternator Cover may be an indicator of loose fasteners.

...The shell of the Starter Clutch Assembly can move/spin over the top of

the three attachment bolts stopping the Assembly to function to start the

engine.

...The Flywheel removal is best done with a gear puller designed for the

specific job. Shops may not have this type of puller and my end up

using hear and/or banging on the crank/flywheel.

...Expect to service a Vmax Starter Clutch every 20+/- miles.

More specific procedures,

explanations, information follow below.

Also Thomas Powell's page has good info and pics:

http://imageevent.com/tppjr

http://imageevent.com/tppjr/modifications/starterclutchfix

|

Microfiche and Parts Sources

(links old, untested)

http://www.yamaha-motor.com/products/categories/2/mcy/yamaha_motorcycles.aspx

http://www.knmotorcycles.com/ K&N Cycles will give VMOA members

a nice discount.

http://www.rivamotorsports.com/

http://216.37.204.203/Yamaha_OEM/YamahaMC.asp

http://www.bikebandit.com/partsbandit/Default.asp|

www.partsfish.com

www.pcwracing.net

Has a gear puller that works, plus has a 'solution' to the starter clutch issue.

I bought his gear puller with worked perfectly. I sent my flywheel and

start clutch assembly to pcw racing for his fix, which is basically permanent.

Fiche from BikeBandit

2004 prices

Crankcase cover fiche from

BikeBandit

Stator fiche from BikeBandit

Starter Motor fiche from

BikeBandit

Starter Clutch Assembly from

BikeBandit

Same operation as outlined above, 'by

the book,'

or extracted from various manuals and resources with

personal ideas.

Vmax Starter Clutch Servicing

Steps in Order

Source information from Clymer's,

Haynes', Factory Service Manuals and assorted saved Vmax list posts.

Tool suggestions:

Gear puller, made to fit the job.

Air impact socket, shallow, six point, 9/16 inch, for gear puller bolt.

Air impact gun, 1/2 inch, with 120-130 lb of air pressure from the compressor.

Hex sockets, 4mm, 5mm, 6mm, 8mm

Open end wrench, 32mm; or large adjustable spanner, to hold crankshaft while

removing crank nut.

Sockets, metric set to include, 10mm, 12mm, 19mm

Breaker bar, large!, to break the crank nut.

Assorted rachet handles and extensions.

Slip ring pliers.

Oil drain pan, rags, paper towels.

Parts:

Starter gear, Yamaha #26H15517-00

Starter clutch bolts, three, Yamaha #91317-08-0814

Starter clutch kit, Yamaha #11H-15580-00

Alternator cover gasket, Yamaha #3JP-15451-01

Gear cover gasket, Yamaha #3JP-15461-01

Materials:

Red Locktite, possible.

Brake cleaner, to degrease surfaces, possible.

Gasket sealer, possible.

Replacement engine oil.

Hints:

...Read/review the procedures several times before starting.

...Have a digital camera and take numerous pictures before starting the next step.

...Have some small containers, pop flats, zip locks and labeling materials

available to keep parts separate and organized.

...Have the correct tools for the 'job.' Use a large floor tray to hold

tools a

...Some torque values have been listed, and a good torque wrench should be used

for major components such as the crank bolt. However, for some less

critical fasteners such as cover or seat fasteners, a 'feel' for the correct

snugness may be just as good or even better since torque values for some

fasteners may be to much.

...Do not bite off more than one can chew! A shop repair may be your best

option.

Preparation for Gearcase and Alternator Cover Removal:

...It is not necessary to drain the oil. There will be some oil loss when the gear case cover is

removed, so this may be a good time to drain and change the engine oil. Or

the old oil can be topped off after the starter clutch operation is completed.

Rider Seat Removal:

...Unsnap the seat backrest. The same as for filling up with fuel.

...Hint...Slide the 'backrest' forward which will expose the front/rider seat screws.

...Remove the seat screws on both sides.

...Pull the seat rearward to disengage the seat's front tap from its bracket.

...Lift back and up, and remove the seat.

Rider Seat Installation:

...Slide the forward seat tab into its bracket, but sure it is in place.

...Install the seat screws and firmly tighten.

...Slide the backrest back into position before pushing it down into locking

position.

Side Cover:

...Remove the two two hex screws. There will be washers behind the

screw heads.

...Carefully pull the top out a little while lifting upward to release the cover

from the frame tab at the bottom.

Side Cover Installation:

..Fit the cover into the frame tab.

...Install the cover screws/washers. Torque to 7N-m or 62ft-lb.

Suggestions/Hints:

...Disconnect the negative battery terminal and insulate from touching anything.

...At this point take a complete series of digital pictures around the left side of

the Vmax to be used as reference when re-installing the stator and pickup coil

connectors, the wiring ties, the wiring, peg, brake pedal, covers replacement.

...Disconnect the three-pin stator connector and the pickup coil connector from

their mates on the wiring harness.

...Open the clamp and release the alternator wires from the frame.

...Open the cable ties that that bundle the wires together.

Left-side Rider Footpeg Removal:

...Remove the two mounting bolts at the bottom of the footpeg bracket.

12mm socket.

...Lower the footpeg from the frame>

Footpeg Installation, is the reversal. Torque to 10N-m or 89ft-lb.

Shift Lever Removal:

...Take note of the dot on the shift rod that aligns with the crack of the shift

lever.

...Loosen the clamp bolt on the shift lever. 10mm.

...Pull the shift lever from the shift shaft. The shift lever must be

reinstalled in the same position so take note of the index mark on the shift

shaft that will align with the gap in the shift lever.

...Remove the snap ring and its washer from the shift pedal post.

...Pull the shift pedal off its post. Pull the shift lever from the

splines of the shift shaft.

Shift Lever Installation:

...Is the reversal of the removal.

...Lubricate the pivot post on the shifter bracket with waterproof lithium

grease.

...Place the shift lever on the shift shaft with the gap in the lever aligned

with the mark/dot on the shift shaft.

...Torque for the shift lever clamp bolt is 10N-m or 89 ft-lb.

...Be sure the snap ring is seated into its groove.

Middle Gearcase Cover Removal:

...Loosen the middle gearcase cover bolts in a star/crisscross pattern.

5mm hex. When removing and installing the bolts to any type of cover use a

star pattern. Be ready for oil leaking from the cover when it loosens.

...Watch for the copper crush washer beneath the bottom bolt of the middle

gearcase cover. A new crush washer should be ordered and installed at this

point during re-assembly.

...Remove the two forward gearcase cover bolts that also hold the shift lever

bracket and remove the bracket out of the way.

...Remove the rest of the gearcase cover bolts and pull/release the middle

gearcase cover. Watch for a moderate amount of oil releasing as the cover

comes off. Watch for two steel dowel pins on the lower sides of the

cover/case.

...Remove the gearcase gasket from its location. Carefully clean all

gasket residue from both the cover and case surfaces, and wife clean for

re-installation of the cover.

Middle Gearcase Cover

Installation:

...Install a new middle gearcase cover gasket.

...Place the two dowel pins into their position in the crankcase of the engine.

...Hand start/tighten the gearcase cover bolts. Again in a star pattern.

...Be sure to place a new copper washer behind the head of the correct bolt at the

bottom of the cover.

...Evenly/gradually tighten/torque to 10N-m or 89ft-lb.

Alternator Cover Removal:

...Open connector holding the

alternator wires from the frame.

...Clip the cable tires that bundle the alternator wires together. Take

digitals or make a drawing so that relocation of the wires and other steps can

be reviewed for re-assembly.

...Loosen then remove the alternator

cover bolts in a cross fashion.

...Remove the alternator cover. Be careful to retrieve the two steel dowel

locator pins between the alternator cover and engine case.

...Remove the alternator cover gasket,

which my have stayed on the cover or may be still on the engine case. A

new gasket should have been ordered and ready to install upon re-assembly.

Be sure both the crankcase and the alternator cover are clean of old gasket

material, oil, debris for re-installation.

Alternator Cover Installation is

just a reversal of the removal:

The two dowel pin locators should be in place on the crankcase.

Install a new alternator gasket.

Hand install the alternator cover bolts and finger tighten in a crisscross

fashion. Snug the bolts down with a socket set in the same manner, then

use a torque wrench to torque the bolts to 10N-m or 89ft-lb.

Install the shift lever so the slot in the lever aligns with the index mark on

the shift shaft. Tighten the shift lever clamp bolt to 10N-m or 89ft-lb.

Rotor Bolt Removal:

...Observe rotor bolt through the middle of the flywheel and the five sided

'head' on the flywheel center for holding it in place when the rotor bolt is

broken loose.

...Using a 32mm (1 1/4 inch) open end wrench, Yamaha sheave holder (#YS-01880), or a large

adjustable spanner (Crescent wrench), hold the flywheel. A second person

may be needed for this operation. An 1 1/4 inch open end wrench works very

well for this operation. If case guards are installed the wrench handle

can be blocked on the guard.

...Using a six-point (not twelve point) 19mm socket on a long/big breaker bar or

rachet,

break loose and remove the rotor bolt and its washer. If this bolt is

difficult to break loose, and if the situation, the larger/longer the breaker

bar, plus a 1/2 socket and bar, may be the solution.

...There is an oil wire inserted into the back/center of the rotor bolt, so find

it. The oil wire may come out with the bolt or remain in the crankshaft.

Find the oil wire and get it back into position in the center of the rotor bolt

for re-installation.

The Flywheel Puller, a major issue:

...Puller options:

Use flywheel removal ideas from the various Vmax forums/lists.

Yamaha number YU-33270 and puller adapter number YM033282.

Make your own by Thomas Powell

http://imageevent.com/tppjr/tools/modifiedflywheelpuller

Buy one from PCW Racing Inc.

http://www.pcwracing.net/featured.htm

Note: I bought/used the PCW Racing flywheel puller,

and sent the flywheel/stater.clutch assembly to PCW Racing for his permanent

'fix.'

(I assume this service is no longer operational, but have not checked.)

(Pics of the puller and returned flywheel package are in the photo sequence.)

http://public.fotki.com/iowaz/iowaz-cycles/vmax-starter-clutch/

...A functional flywheel puller is

mandatory as the flywheel is on a long tapered bore/shaft so the contact surface

between flywheel and shaft produces a highly bonded surface, therefore it can be

very difficult to break the flywheel loose from the crankshaft.

....Also the

flywheel puller bolts have to be very long to reach from the puller plate down

to the flywheel puller insert threads. These long bolts will stretch under

the high loads placed on them making if often impossible or nearly impossible to

break the flywheel loose. Often long bolts stretch, so when the flywheel

does release the bolts contract and can shoot the flywheel across the room, so

be careful if not using a puller with long bolts and not one with studs as shown

on the above link.

REMOVE THE IDLE GEARS, FLYWHEEL

5. Remove the flywheel bolt.

Check for clog of

the oil passage in the flywheel bolt and clean if necessary.

Remove the plain

washer.

Remove the pin.

6. Remove the flywheel using

an appropriate puller. When removing the flywheel, do not

allow the oil baffle plate to touch the projections on the flywheel.

7. Remove the woodruff key on

the crank.

Remove the

Starter Clutch Gear.

Flywheel Removal

I chose to buy the puller sold by PCW Racing, which worked great as described

below.

...Thread the three 8mm socket head set screws supplied with the puller into the

three threaded puller holes on the flywheel using a 4mm hex head wrench.

Snug down until they are firm/tight.

...Screw the three chrome moly stands/spacers supplied onto the 8mm set screws

and snug down with your hand.

...Bolt the puller to the stands with 3/8 16 socket head machine screws

supplied. Be sure the hardened washer of the two is against the puller

head. Tighten these bolts down tight with an 8mm allen wrench, making sure

the puller is centered on the flywheel.

...Use a 1/2 inch air impact wrench with a 9/16 inch six point shallow impact

socket to drive the puller. Air pressure of 130lbs is desirable. Hit

the air/trigger on the air impact wrench, and if the flywheel does not release

and start sliding off, hit the air again. If the flywheel still does not

release, retighten/firm up the fasteners on the gear puller. Followed by

lightly/carefully tapping the gear puller bolt to send a slight shock wave down

the crank which may help break the bond between the crank and flywheel.

But be very carefully not to 'pound' on the puller/crank setup, just a light

couple of taps. Then again continue with hitting the air again. The

flywheel should release with any significant problems using a modified gear

puller and air impact wrench.

...Remove the flywheel from the crankshaft, but be careful it does not touch the

oil deflector which hangs over the area. The flywheel may need to be

rotated to miss the oil deflector.

...Remove the Woodruff key (crescent shaped piece of metal) which is likely

still in the grove down the crank shaft. If not, it is stuck in the

flywheel. Place the Woodruff key in a safe place as it is easily lost.

Another option?...If you do not have a compressor and air impact wrench

you can

try a long breaker bar and socket. You can also try a gear puller with

just the normal long bolts to reach the flywheel puller threads but the history

of that set up is that the bolts stretch under the great force applied and often

break if not high strength bolts. High strength bolts often stretch enough

that when/if the flywheel releases from the crank the puller and flywheel are

shot with a rubber band effect across the room, so be careful, have eye/hand

protection, and have a soft stop set up for the flywheel, such as rugs/blankets.

The flywheel is a $500 items so you do not want to ding it up.

Inspection of Parts:

...Wipe the parts clean or clean with a solvent and dry with compressed air.

...Carefully check the flywheel for cracks/breaks/chips. Replace if

damaged. A flywheel break-up at high speeds can throw fragments into the

engine.

...Inspect the crankshaft and threads of the flywheel bolt.

...Take a good look at the starter and idler gears and their shafts.

...Look for worn/broken teeth on the starter wheel gear and for worn patches on

the smooth bearing surface of the starter wheel gear created by the rollers of

the starter clutch. Inspect the rollers in the starter clutch.

Generally it is best to replace the entire starter clutch assembly and

starter wheel gear.

Starter Clutch Disassembly:

...Place the flywheel face (outside) down.

...Rotate the starter wheel gear counterclockwise to remove it from the

flywheel. The gear sits over the starter clutch housing.

...Press the spring cups against the spring and remove their rollers, then

remove the cups and springs from the starter clutch housing.

Installing new

Rollers/Springs/Cups:

...Be sure the large/thin washer is in place in the starter wheel bore as

the rollers ride over the outer edge of this washer.

...Fit a new cup on a new spring end set spring end first in place in the

starter clutch housing. The roller will ride on the cup end.

...Compress the spring by pressing on the cup end and insert a roller into the

housing, releasing the cup/spring.

Flywheel Installation (by the

book):

...Clean all the oil from the crank taper.

...Install the starter wheel/gear into the flywheel.

...Replace the Woodruff key into the crankshaft keyway.

...Align the flywheel keyway slot with the Woodruff key. Slide the

flywheel on to the crankshaft

...The starter wheel gear needs to engage the starter idle gear.

...Place the oil wire into the flywheel bolt.

...Start he flywheel bolt/washer by hand into the end of the crankshaft.

...Hold the flywheel with the 32mm or 1 1/14in or crescent wrench and torque the

flywheel bolt to 130N-m or 96ft-lb.

...Be sure the starter idler gear and idler shaft are installed correctly.

Pre 2004

Vmax List Posts Regarding the Vmax

Starter Clutch

First, some personal

thoughts:

...The posts are to give one an idea of some of the past

discussions regarding the Vmax starter clutch. There were valid ideas

being shared, but also some procedures tried/used that should be avoided, so

read the past posts with that insight in mind.

...Although not being any sort of an accomplished mechanic, I need to share some

personal opinions at this point in time before reviewing past posts.

...It should be noted about the concern mentioned regarding newer Vmax's

possibly having a issue of no or incorrect locktite being used on the three

bolts holding the starter clutch assembly to the flywheel. These bolts

apparently come loose letting the starter clutch wobble around and possibly

release parts as the flywheel spins at high speeds. Release of parts in

this area would/could cause some serious damage. The starter clutch

assembly could be inspected by opening up the case, observing and feeling the

starter clutch assembly while on the installed flywheel. The flywheel

would not have to be removed for this inspection.

...Using heat on the flywheel to cause it to expand and release some of its

pressure on the crank should be avoided, IMO. Turning the crank bolt out a

couple of turns and leaving it in place so that the flywheel does not 'fly' off

should be avoided, IMO. The end of the crank is indented to fit the end of

the gear puller, so if the bolt is in place, the gear puller would be resting on

the crank bolt putting very excessive pressure on the treads in the crank.

Pounding/hammering on any part of the crank, flywheel, puller should be avoided,

IMO. A very light tap might be used on the puller bolt, but that is all.

...IMO, it is well worth the cost or effort to make or buy a gear puller with studs

instead of using long bolts which stretch/break. Also, the contact of point of the

puller to the crank shaft should be flat or machined flat to mate. The

puller center bolt end should not be pointed! It is also worth

finding a compressor and air impact wrench to use with the correct gear puller.

With that said, some of the following posts are left intact as they give

examples of using 'manual' methods of removing the flywheel that some people may

need to try due to equipment availability.

...A general heading has been added to each posts series to give an overview of

the post's topic.

PAST POSTS

My starter grinds. How can I fix it?

Note: This project is not for mechanical beginners. I am not responsible for

damage you may cause to your motorcycle by attempting to follow this without

sufficient experience. You will probably have to replace the starter clutch. It is bolted to the

back of the flywheel. It's not that technically difficult, but the flywheel can

be a bear to get off of the crankshaft.

Link to remainder of info with pics:

http://home.nc.rr.com/vmaxfaq/StarterClutch.htm

For those of us who have delt with

the clunk/crunch/whir of a failing

starter - John Ganey offers his very own solution -

www.pcwracing.net

Flywheel

Retaining Bolt

...My

starter clutch is

hitting and missing. Trying to

remove generator flywheel thing to get to it, but having no luck!

Any one got any tips. Is the retaining bolt in the end of the

crank right or left hand thread?

Bolt on end of crank is right hand. Use at

least grade 8 bolts on puller

or wasting time. Also only loosen bolt on end of crank a couple of

turns, don't remove, so it doesn't fly across the room when it comes

loose.

Don "Old Man" Smith

The flywheel has a "sculpted hexagonal

bolt like" section for you to hold on

while loosening the bolt. DO NOT try turning that part as if was a bolt!!!

Believe me it won't turn (don't ask me how I figure that one out :-)

Use a harmonic puller or a steering wheel puller with machine grade (black

looking) bolts. Also Make sure that the bolts (3 of them) are at least 4 1/2

inches long. It is also a good idea to loose but not remove completely the

bolt securing the flywheel in place. The flywheel/puller will fly across the

room!!!! Once you move it half millimeter it will just pop out.

Apparent Issues

on Newer Vmax's with the Bolts Holding the Starter Clutch Assembly to the

Flywheel!!!

...Has anyone in the group had any experience

removing and repairing

starters. The unit on my '97 spins but doesn't engage gears every

time.

If you sometimes start it is probably the

infamous STARTER CLUTCH problem

NOT THE STARTER.

My '97 with 10K miles is starting

to show signs of starter clutch problems

too.

A horrendous grinding noise sometimes when starting.

You will need to pull the LEFT cover and remove the fly wheel.

The starter clutch is under the fly wheel. I think about $150-200 for

the rebuild kit.

Get a service manual...... and I think you will need to do more looking about

the starter clutch in the archives...there is a complete procedure on

how to do it some where here...maybe someone will point it out.

It seems the factory was lacking with the

newer bikes. The bolts that hold

the clutch in are suppose to be cemented in with locktight and then the ends

are peened so the bolts will not come out. Most of the new bikes that have

had problems have been peened but no lock tight. It was good that they were

peened at least with mine it was all that kept them from falling out and

bouncing around the engine. Most of the bikes that have trouble seem to be

newer.

Flywheel will

not come off

...Well I attempted to inspect my starter

clutch, but could not remove the

fly wheel even after buying a puller and heating around the fly wheel

bore. After inspecting the clutch bolts, the movement of clutch and the

condition of the gear teeth as best I could, I gave up and put

everything back together. I only put dope around the cover where the

gasket had separated thinking the local dealer was going to have to tear

it all down again anyway. Just for the heck of it I tried to start it

one more time and behold, the bike fired up! In fact the clutch hasn't

slipped in five days!!!......What's up with that!!!

Another thing that I noticed was the presence of motor oil inside the

fly wheel cover along with the white grease. Is this normal?

Gear

Puller Bolts

Can someone tell me the size of the three

bolts used to attach

the puller to the flywheel? I know they should be at least grade 8 and can get an

appropriate length but haven't got anything on the shaft/thread size.

Okay,

They are M8x 1.25 same as the

pinch bolts in the

triple clamps among other things. The new problem is where to get them in grade 8.

The 2 places

I just went don't have any grade8 metrics. any suggestions?

---

http://www.mcmaster.com/ enter "2919" in find box

They have Class 12.9 metric bolts, but come in a box of 100.

---

You can obtain Grade 8 bolts in "inch"

sizes .. they are rated for a

minimum tensile strength of 150,000 psi.

Believe it or not you can also get a Grade 9 now ... 180,000 psi tensile

strength, 20% higher than the standard for Grade 8 cap screws.

However Metric strength ratings are different than those for

"inch" sizes.

Metric Class 12.9 (the highest metric strength class) exceeds the strength

of Grade 8. Minimum tensile strength is 174,000 psi.

Metric Class 10.9 is comparable to Grade 8. Minimum tensile strength is

150,000 psi.

So, it is safe to say you will not be finding any Grade 8 metric

bolts.

Go get what you want at McMaster Carr .. the stuff shows up like the very

next day for peanuts ...

http://www.mcmaster.com/

You can run yourself ragged trying to find a decent variety of metric in

local shelf stock (in the US anyhow).

Starting

Problems

I own a 1995 V Max, Stock except for

TBoost, which I just installed this year. The problem I am having is with my

starting system. I hit the start button, and it sounds like the starter and

gears are just spinning. Sometimes for a brief second it will catch, and almost

start, and it did start once. I thought at first bad starter motor, so I

replaced it with a new one, and had the same result. After a little searching

here, I now think it is the starter clutch. I removed the side case, and

removed the flywheel. As far as I can tell, everything looks good. Anything I

can do to get it to fire up, or just replace the clutch also. I purchased it

brand new, and it has 2500 miles on it. Any help appreciated thanks.

Very Important

Information Why the Flywheel Bolt Needs Totally Removed

Before Pulling the Flywheel!!!!!!

That was one ugly picture

of the loose bolts. I was much luckier. My bolts were

only about 1 turn loose and no damage to anything. I only drove about

20 kms after the noise started.

It is referred the puller bolts as being grade 8 but it has been referred to

replace the 3 starter clutch bolts with grade 8's. Hoping that

reusing the original bolts is alright because they are thoroughly red

lockite'd in place although the flywheel is not re-torqued so if

necessary can get it off without borrowing another puller.

Discussions on this

repair have noted / warned that the flywheel will "fly" off the arbor

when it finally releases. One response indicated using an impact gun

for additional pressure and most have recommended leaving the flywheel

bolt only a couple of turns unscrewed so the flywheel cannot "fly" off.

I did not have an impact gun, so I was tightening the puller as much as

possible with my 1/2" drive socket (and using a spanner as shown in the

manual) and then hammering quite heavily on the puller center bolt.

After my second unsuccessful attempt, I tried to put the socket back on

the puller center bolt, which I couldn't because the hammer had

mushroomed the head (file, file). This didn't seem right (duh!).

Then I remembered something about tapered arbors from decades old

machine shop. Tighten a LITTLE, then tap (not hammer), repeat as

often as necessary. So instead of torquing as much as possible and then

hammering, I did a little at a time and it came off with seemingly much

less torque on the puller center bolt and the flywheel was easily

retained from flying off by just placing my hand in front of it while I

tapped.

I suspect that initial over-torquing of the puller center bolt is

contributing to the excessive force then required to release the

flywheel from the arbor.

Not only did my procedure seem to eliminate the need to leave the bolt

in place to prevent the flywheel flying off but the flywheel center bolt

is not designed to be left in place regardless of which pulling method

you use.

Once this bolt is removed there is a large taper section at the mouth of

the bolt hole which is designed for the tapered slider that fits into

the end of the puller center bolt. Leaving the flywheel center bolt in

place causes whatever torque being applied to the puller to be applied

to the threads of the center bolt. This can't be a good thing.

Some Have Tried

Heat When Removing the Flywheel, but Something to Avoid IMO

Real character builder, isn't it...

Heat is the trick. I wasted 3 pullers myself. I only used 1 propane torch

but, Propane won't generate enough heat quick enough. What I did was heat,

turn, heat, turn. Don't force the puller. Took a couple days because I had

to keep running back to sears for a new puller... 3 different sears stores..

When the flywheel finally comes off, it will POP and fly a few feet. Watch

you shin bone..

Also on the puller, make sure to replace the bolts with at least grade 8 or

better. Stock puller bolts are soft and will stretch and bend. It is a bitch

of a job but you can do it..

You Can See the

Flywheel Removal Problem Kept Coming Up in the Discussion

Do you know some trick for remove the flywheel??

---

you need to use bolts that are at least grade 8 or better.

Bolts that come with some pullers are grade 5 or less and stretch.

---

The center bolt stays but keep it loose with a little more than a 1/8

gap.. The center bolt is what your going to pull against and it will

keep the flywheel from flying off...

Put some tension on the puller.. Now take a flat ended bar or similar,

hit around the HEX part of the fly

wheel where it's like round and flat.. I did this in 3 spots and the

thing popped off like nothing.. Now if the pulled bolts stretch, get

the matching 8 grade bolts..

---

Connect an air impact wrench that is being fed

300 (120+) psi and use the

flywheell puller. This amount of psi can be found at a local tire

replacement company. It can come off

fairly simply or like mine it can be a mother.....

Use the grade 8 or better bolts. I had to use the next

grade up.. Torque down on them and make sure they are all evenly

applying pressure on the puller. Torque the main bolt on until you

can't anymore (by hand) and then tap on the end of the bolt. I had to

hit it fairly hard, but some say tap lightly. Then torque the bolt with

the air wrench til it seemingly stops and tap some more.

Torqueing/tapping then tightening is the procedure. If your lucky it

will come off and all will be right with the world. As long as your

still torqueing then your doing something so don't freak out when you

realize that you have been at it for a half hour or an hour.

Is the Starter

Clutch Really the Problem?

You may have answered this and I missed it,

but now that the stator cover is

off, have you examined the starter clutch to be sure it is the problem?

Can you move the starter gear in and out on the crankshaft, or wobble it, or

rotate it in both directions? Or did you find loose screws in the bottom of

the stator housing? You don't want to take things apart and fix them when

they aren't broken.

---

The starter clutch can still be cracked and

not detected from feeling

things. Once the fly wheel is off, the baffle plate (starter clutch assembly

case) screws need to be

checked too. That is what came loose on mine the 1st time.. Caused it

to bind and crack

---

I should add that the 2nd time my starter

clutch went bad was from

the starter clutch bolts loosening..

Cycle

Shops May Not be Able to Handle the Flywheel Removal

My mechanic is having problems removing my flywheel to get at a damaged starter

clutch gear. He has broken two flywheel pullers already. I don't know whether

they are Vmax specific flywheel pullers or not.

My service manual says to use the Flywheel Puller (YU-33270) with the puller

adapter (YM-33282) is this an absolute requirement and what does the adapter do?

Also, does anyone have any specific advice for removal of a stubborn flywheel?

What is

Going On With My Starter?

Starter been grinding too? It's the starter

clutch. Makes a clunking

noise at idle, sounds just like a rod.

http://home.nc.rr.com/vmaxfaq/StarterClutch.htm

Good Grief!!!!!

A Must Read Example of Taking the Problem to the Un-informed.

This example also shows that some pullers have a 'pointed' contact

point with the crank shaft, which IMO is a no-no. The 'face' of the puller

needs to be flat or machined flat to 'fit' the correct size/fit of the end of

the crank.

Please excuse my motorcycle ignorgance. I

have had a rough sound when

starting recently. Today this sound evolved into no start at all. When I

try to start the starter doesn't seem like it is engaging at all, just a whine.

On a car this would be an easy diagnosis and fix. The starter is bad.

Go get one and replace it. A couple of screws, a couple of wires and,

Wella, no more problem.

Maybe it's just my lack of confidence that makes me feel everything about

the bike is so much more complicated but then again when you hear related

terms that you don't know about, it makes you feel as if there is something

else you should know. For instance, I'm sorry but I don't know what a

stator is. I know it's electrical and is something like a coil. I also

don't know what a starter clutch is. What I think I need is a starter

motor. Any info would be helpful, such as, whether this is my problem,

where to get one online, how much to expect to pay, and hints in

replacement.

---

The car starter you talk about in cars has a

Bendix, which is some sort of gear driven by the motor shaft and included in the

starter, that's why you call it an easy fix, since you just have to remove the

whole unit and fix it or replace it.

In our case it is a totally different system, (unluckily for you), specially

when you mention that the starter whines but does not engage, that means that

the motor is working, but not the starter clutch, which is not part of the

starter motor, but fixed to the flywheel on the crankshaft. This element is on

the left-hand side of the motor, and to get to it, you have to remove the big

cover, Remove the flywheel and inspect the clutch and replace it/fix it. As you

have mentioned, since you are not much into bike mechanics, you better take it

to the dealer or better still, find a close by guy in this group that can lend

you a hand, since pulling the flywheel is no joke.

MOST IMPORTANT, the starter clutch is fixed/attached to the flywheel and

the first/one thing that happens is that the fixing screws get loose, then they can

come out and start damaging other engine parts, so I sincerely recommend that

you don't ride or start the bike any longer, till you get the starter clutch

attended; after screws are loose, metal to metal scraping is more than likely,

clutch rollers & springs can break and you end up with an engine full of nasty

pieces moving about......

---

I took your guys' advice and took this job to

the shop. The problem is I

live about 45 miles from a real bike shop, and they have a huge wait for

service. A new bike shop opened very close to me. Not an authorized dealer

mind you but a bike shop.

He could get to work right away and I'd be back up in no time, and besides I

just got my Metzelers and needed to get them mounted anyway.

Well all praise to the V-Max group and the gurus who inform the ignorant

like myself, for the prophecy came true. The flywheel is a b&^%* to get

off. I know you guys are going to know exactly what I'm talking about so I

don't feel awkward in describing it. This guy has a (cheap looking) puller

that has what I would say resembles three fingers and a thumb. It looks to

be cast. I've used a gear puller before for pulleys, and it works on the

same idea but instead of claws grabbing the outside with a center driving

bolt for leverage, it has screws that go through the fingers and thumb and

screw into the flywheel to grab it, and of course the same type center bolt

for leverage.

With this set up he has only accomplished stripping the hardened screws

of the puller. It hasn't stripped the flywheel, yet. He has put heavy psi

on it (the center bolt of the puller has completely flattened its point),

rapped on it with a hammer while under pressure (with protection for the

wheel), and applied heat via torch. Still this flywheel won't come off. He

says that this is the tool all the shops use but when I was talking to

someone else about it he said there is a better puller that grabs hold of

the shaft or something. What do you guys know about these pullers and other

techniques to remove the flywheel? I've told three different shops and

countless others about you Gods of the Max who know all. I know you can

help.

Something else we noticed; of the three screws that hold the starter

clutch, one is tight, one is backed out some, and one is slightly backed

out. The slightly backed out one is loose enough to move by finger but

hasn't backed out much because someone evidently had this problem before and

tapped the end of the bolt enough to mushroom the end. For some reason they

just did that to one of the three bolts. Now it will have to be ground to

be removed.

I was waiting to remove the flywheel/starter clutch to assess the damage

and replace as necessary, but now that this job is such a b&^%*, I'm going

to replace all of the starter clutch including new bolts. My 'mechanic'

also suggested changing the brushes on the starter motor as preventative

maintenance from ever having to remove this damned flywheel again. Any

other suggestions about preventative maintenance in this area would be very

much appreciated as well.

---

Pull the crank out and put it in a press,

or you could try tapping the flywheel in the direction it turns , this seams to

help

last one I did came off easy after it moved a little I think they get spun

against the key and lock on! ( just a thought)

also when it pops off you might lose the magnets and then you will need a new

flywheel :(

---

Thanks a million guys. Great to have you

there, especially in a time of

need. As I mentioned the 'mechanic' was rapping on the side of the flywheel

with a hammer with a rag in between for protection (still left marks). This

didn't get the impact through down to the shaft. I got a direct tip from a

list member, and later he ('mechanic') got the same one,

to hit instead the center bolt of the puller, seems like a simple little

change, but one that could easily not be done. As you know this puller

looks cheap and you wouldn't think right away to beat it with the hammer,

just doesn't seem as natural as hitting the object that you want to come

loose. But now that I know, it seems so obvious. Hitting the flywheel,

especially necessarily padded, just absorbs the blow, but when you hit that

center bolt with all of the pressure on it after cranking it with an impact

transfers all of the impact through the shaft and center of the flywheel and

creates a shockwave. Two blows to the right spot and, Wow! The puller and

flywheel flew across the room and into the wall. No damage. It's back

together and running. I just need to get my tires mounted and I'll be back

on the road later today. Sorry I got a little dramatic "summer's slipping

away". Two work weeks and a weekend in the middle of summer causes frantic

withdrawal in a bad way. Thanks for the warning not to ride (push start).

The head of one of the bolts that hold the starter clutch to the flywheel

was slightly rubbed down. A condition which surely would have caused

problems had I taken the bike on one good ride after it had backed out.

No Loctite

Again, PCWracing's Puller

The starter clutch is most likely your

problem. The 3 bolts holding it

in place often come loose. Serious damage results if max is run and

they come completely out. You need to pull the flywheel to check/repair

it.

The service manual shows loctite on these bolts. Mine had none.

---

I hear the PCW version of the puller does

great. Others have used a rubber mallet and hit the center bolt to loosen

things up, but I don't recommend that. Anyway, PCW says that theirs will remove

all Vmax flywheels on the 1st try.

http://www.pcwracing.net/featured.htm

Questions,

Questions

When I started my bike a few weeks ago (after

sitting for about 2

months) it cranked and fired after a few times. When starting it over

this past weekend it would crank and then starter would spin but kind of

grind. Then hitting the starter it would catch then do the same thing a few

times. My question is where do I pull the cover off to check to see if

bolts are loose? Also should I order a new gasket for the said cover?

And

what else should I look at to see why it might be acting up? It is a 94

and should be a 4 pole starter (How can I confirm?), I have a pc 680

battery and it is up to spec......it showed no sign of being weak at all.

plus just a short while ago I made sure system was indeed charging at idle

and battery when off was fine. Any thoughts and is it hard?

A couple

of years ago I had someone else "fix" it and all was fine till late

---

Mine is doing the same thing. I did this job

on my other engine, before

the swap. It is a pain. You have to pull the entire stator cover, and you

will need a new gasket. Then, pull the flywheel. That is the real pain. Guys

have broken pullers trying to get them off. You'll need a good puller and

probably a torch, to heat the center of the flywheel while using the puller.

Don't stand directly in front of the flywheel, because when it pops, it may

go flying. I dread tearing into this job again.

---

The alternator cover on the left side needs to

be pulled and yet a new cover gasket should be used. Be careful of the stator

when removing the cover. There are also two dowels, make sure they stay in the

crankcase.

The flywheel must be removed to get to the starter clutch, hopefully that's

what's bad....new starter motors are expensive.

---

Isn't there something to look at before

pulling the flywheel? Then

what am I looking for anyway? Loose bolts? If and when pulling the

flywheel what usually needs to be replaced?

---

You can look at the starter idler gears and

the starter shaft. To get to the clutch, flywheel must be removed. I hear PCW's flywheel puller is guaranteed to get the flywheel off in the first try.

It's probably your starter clutch, mine did the same thing. Sounded nasty, mine

was caused by worn clutch bearings.

Crank Bolt and Flywheel Puller Bolts?

Can anyone tell me if the flywheel bolt is left-hand

thread? Also, what size

bolts do I need to screw into the flywheel for the

puller?

---

No, it's right handed thread. The standard

bolts that

came with my puller kit fit the three holes perfectly

so you should be ok if you bought a kit. They might be

10's or 12's, not sure and my kit is not here to

check.

One more thing: I wouldn't heat up the flywheel with a

torch. There are magnets in there and I doubt that

turning them red would do them much good. The best way

to get the flywheel off is to use an impact gun on the

center bolt of the puller. Just be sure to have

something soft underneath it because it probably will

flop off.

---

Well, I bought a Craftsman harmonic balancer

puller and some grade 8.8 M8 x

1.25 x 90mm bolts (no one in my rural area had anything harder). I found

that the flat adapter that came with the puller set perfectly fit inside the

center hole of the flywheel, after removing the bolt. I used a 1/2" drive

air impact wrench to tighten the puller, then tapped on the hex-shaped area

of the flywheel, and on the end of the puller's center bolt. After tapping,

I'd tighten the puller again with the impact wrench. I did this routine

about 4 times and the flywheel popped right off. There was no doubt as to

the problem! All three bolts on the starter clutch were finger loose, and

the side of the thin metal piece that covers the clutch was actually

ruptured. Tomorrow I'm off to the local dealer to see if they have one. If

not, I'll probably be ordering from Scott Powersports, with the VMOA

discount.

What Loctite

Should Be Used on the Three Starter Clutch Assembly to Flywheel Bolts?

When loctiting

the bolts for the starter clutch, what is the minimum time before running the bike? and is blue

loctite the one to

use?

---

Use red, not blue loctite.

---

Used to be only one red loctite. You want stuff that sets up after

heated and doesn't come out. Used it on exhaust manfold bolts, once set,

it took 1/2'' drive impact to remove 3/8'' stud.

----

I've had some bad experiances with the

permanant red

locktit.

I switched to something called 1360.

My currant tube is labeled suzuki so I dont know if

the number crosses with locktit.

Its called med strenght,high heat.

Had very good luck with it.

My 2c...

---

Don't use blue loctite on the starter clutch

bolts. I did and they came

loose again. Did again with red, no problem.

DO NOT DO THIS

(The flywheel bolt needs to be totally removed so that the end of the crank

meshed with the flat main bolt end of the puller.)

When removing the

flywheel, loosen the bolt that holds it on, don't take it out. Back it

off maybe 2 turns, then it won't bite you.

DO NOT HAMMER

ON THE CRANK OR FLYWHEEL

I would be very careful hitting the center

bolt. Remember that the flywheel

is attached to the crank and the shock will go through the crank too. I

would think the side load on the bearings would not be too good.

Your best bet is to get a quality puller and replace the bolts with at least

grade10 if it does not come with them (usually the ones that come with the

puller are not long enough). I got a Sears Craftsman just because it is

guaranteed but I think I pushed it pretty much to it's limit. Heat is pretty

much a necessity. The faster you can apply it AFTER you have max torque on

the puller the better. The object is to heat the flywheel fast enough so

that it heats and expands and the heat does not have time to transfer to the

crank.

As many have said before, beware when she POPS loose and I do mean POP!! It

will fly across the room.

Replace All

Parts

Replace all the starter clutch parts. I am

going thru this right now. My

screws were tight, but the clutch slipped. In addition, the roller pins in the clutch wear

little bevels in to the idler gear where they contact it. I did the

research, you can benefit. K&N cycles in Oklahoma (on the VMOA vendor list)

absolutely had the lowest price and will ship directly to your home. Cost

for clutch with all parts, 3 new screws, and idler gear, and....shipping is

about $110. No one can beat that price. Contact them and give them your

VMOA number for the discount!

It never fails, whenever you spend and ridiculous amount of time

polishing, detailing and improving the little things, something major

goes wrong. Today, my starter would not engage and it produced a rapid

clicking sound. I dared not try to start it again fearing that I'm

grinding gears. So, here's the good news. A quick search of the mail

archives

http://www.mail-archive.com/v-max@sayegh.org/ returned a

message from Thomas Powell who had the same experience.

I took my side cover off and to my relief, the gears looked fine. But,

sure enough, the three bolts that hold the starter clutch against the

flywheel had come loose. When I manually moved the larger starter gear,

I can clearly see the bolts moving from within the flywheel. So, I went

out and got a harmonic balancer remover for $15 and attempted to removed

the flywheel in order to "loctite" and tighten the three bolts.

Amazingly, I ended up stripping the center bolt on the harmonic balancer

remover and that damned flywheel didn't move a single nanometer.

Tomorrow, I'll get some longer bolts to attach to the flywheel and

thread the center bolt past the stripped section. I soaked the section

between the flywheel and the crankshaft with liquid wrench and will let

it sit overnight. One thing I didn't do was hit the center bolt with a

hammer to set up some vibration. I'll do this tomorrow once I get

longer bolts to attach to the flywheel. Once I get that flywheel off,

the rest should be easy.

Something I had mentioned before and will again. When

removing the

flywheel, loosen the bolt that holds it on, don't take it out. Back it

off maybe 2 turns, then it won't bite you.

I would be very careful hitting the center bolt. Remember that

the flywheel

is attached to the crank and the shock will go through the crank too. I

would think the side load on the bearings would not be too good.

Your best bet is to get a quality puller and replace the bolts with at least

grade10 if it does not come with them (usually the ones that come with the

puller are not long enough). I got a Sears Craftsman just because it is

guaranteed but I think I pushed it pretty much to it's limit. Heat is pretty

much a necessity. The faster you can apply it AFTER you have max torque on

the puller the better. The object is to heat the flywheel fast enough so

that it heats and expands and the heat does not have time to transfer to the

crank.

As many have said before, beware when she POPS loose and I do mean POP!! It

will fly across the room.

My starter will spin disengaged when the bike is cold. I have

to play with it until will finally engage completely to get it to turn over.

But if it is warm or at operating temperature, the starter works fine.

I'm going to pull the fly wheel tonight and check those three bolts to see if

they are loose or anything else that might be a culprit.

Replace all the starter clutch parts. I am going thru this right

now. My

screws were tight, but the clutch slipped. Take a look at the pics and you

will see why it slipped. In addition, the roller pins in the clutch wear

little bevels in to the idler gear where they contact it. I did the

research, you can benefit. K&N cycles in Oklahoma (on the VMOA vendor list)

absolutely had the lowest price and will ship directly to your home. Cost

for clutch with all parts, 3 new screws, and idler gear, and....shipping is

about $105.00. No one can beat that price. Contact them and give them your

VMOA number for the discount! In the parts pic, #6 is the idler gear, #7

the entire clutch assy, and #11 the screws

It's been awhile since I did mine

but, let me try to explain. Do you have tools?

You will need a wheel puller, impact wrench (I didn't use one but

would be nice), sedylene<spelling) torch, sockets, torque wrench,

allen keys?

Got the repair manual? You can down load that if you need one.

The fly wheel will need to be removed. This is a bitch without the

proper tools. The 8 grade bolts Don speaks of are the upgrade for the

wheel puller you will end up buying if you don't have one. Anything

less will bend. Just match the bolts with the grade 8 bolts.

Pull side cover(s) on the shift side of bike. You will need to remove

the shifter, foot rest, etc. to do this. There it is, the FLYWHEEL..

Get the puller set up on there and start to crank it tight. While

doing this you want to use the torch to heat the flywheel center.

Heat, crank, heat, crank. It will be a good idea to stay clear of the

front of the flywheel. Like Don say's, you will shit when it POPS. It

will fly through the air when it goes. It is heavy enough to hurt

(don't let this scare you) you if your in front of it.

Now the rest is cake once the flywheel is off. The gear pulls off and

there is the starter clutch. Did anyone get the stuff off Paul's

site? There was a nice page showing the part and what to look for.

Anyway, sometimes it is only a bad case of loose bolts. Sometimes not

and the SC is cracked. Inspect all the bolts on the baffle plate

above too. Mine were loose there also.

I went through 3 wheel pullers before I finally got my flywheel off.

I used a propane torch. It wasn't hot enough.

It's not as tough as it sounds. Good luck. You can pop the clutch in

2nd gear to get you started. I parked on hills allot till I fixed

mine.

Well don't use a sledge hammer :)) Been pulling gears,

flywheels,

bearings, balancers, etc for many years with the hammer method with no

problem . It is a common practice in the professional shops . Much safer

and quicker than heat . I've pulled my max flywheel off twice and at

least another half of dozen others using the method . It is a simple

physics law . An object at rest tends to remain at rest .

Last week one of the locals, that is also a mechanic, brought over to

me a flywheel and starter clutch unit to look at . I asked him if he had

any problems getting the flywheel off and all he said was " No I just

wacked the puller a couple of times and off it came" .

Use whatever method you are comfortable with .

I use a brass mallet for jobs like this, there is no problem

for

crankshaft at all. All you are doing is taking up the thrust clearance,

it can't go anywhere else.

Bolt on end of crank is right hand. Use at least grade 8

bolts on puller

or wasting time. Also only loosen bolt on end of crank a couple of

turns, don't remove, so it doesn't fly across the room when it comes

loose.

The flywheel has a "sculpted hexagonal bolt like" section

for you to hold on

while loosening the bolt. DO NOT try turning that part as if was a bolt!!!

Believe me it won't turn (don't ask me how I figure that one out :-) )

Use a harmonic puller or a steering wheel puller with machine grade (black

looking) bolts. Also Make sure that the bolts (3 of them) are at least 4 1/2

inches long. It is also a good idea to loose but not remove completely the

bolt securing the flywheel in place. That thingy will fly across the

room!!!! Once you move it half millimeter it will just pop out.

I use a brass mallet for jobs like this, there is no problem for

crankshaft at all. All you are doing is taking up the thrust clearance,

it can't go anywhere else.

Bolt on end of crank is right hand. Use at least grade 8 bolts on puller

or wasting time. Also only loosen bolt on end of crank a couple of

turns, don't remove, so it doesn't fly across the room when it comes

loose.

The flywheel has a "sculpted hexagonal bolt like" section for you to hold on

while loosening the bolt. DO NOT try turning that part as if was a bolt!!!

Believe me it won't turn (don't ask me how I figure that one out :-) )

Use a harmonic puller or a steering wheel puller with machine grade (black

looking) bolts. Also Make sure that the bolts (3 of them) are at least 4 1/2

inches long. It is also a good idea to loose but not remove completely the

bolt securing the flywheel in place. That thingy will fly across the

room!!!! Once you move it half millimeter it will just pop out.

The flywheel has a "sculpted hexagonal bolt like" section for you to hold on

while loosening the bolt. DO NOT try turning that part as if was a bolt!!!

Believe me it won't turn (don't ask me how I figure that one out :-) )

Use a harmonic puller or a steering wheel puller with machine grade (black

looking) bolts. Also Make sure that the bolts (3 of them) are at least 4 1/2

inches long. It is also a good idea to loose but not remove completely the

bolt securing the flywheel in place. That thingy will fly across the

room!!!! Once you move it half millimeter it will just pop out.

If you sometimes start it is probably the infamous STARTER CLUTCH problem

NOT THE STARTER.

My '97 with 10K miles is starting to show signs of starter clutch problems

too.

A horrendous grinding noise sometimes when starting.

You will need to pull the LEFT cover and remove the fly wheel.

The starter clutch is under the fly wheel. I think about $150-200 for

the rebuild kit.

Get a service manual...... and I think you will need to do more looking about

the starter clutch in the archives...there is a complete procedure on

how to do it some where here...maybe someone will point it out.

It seems the factory was lacking with the newer bikes.

The bolts that hold

the clutch in are suppose to be cemented in with locktight and then the ends

are peened so the bolts will not come out. Most of the new bikes that have

had problems have been peened but no lock tight. It was good that they

were

peened at least with mine it was all that kept them

from falling out and

bouncing around the engine. Most of the bikes that have trouble seem to be

newer.

Well I attempted to inspect my starter clutch, but could not remove the

fly wheel even after buying a puller and heating around the fly wheel

bore. After inspecting the clutch bolts, the movement of clutch and the

condition of the gear teeth as best I could, I gave up and put

everything back together. I only put dope around the cover where the

gasket had separated thinking the local dealer was going to have to tear

it all down again anyway. Just for the heck of it I tried to start it

one more time and behold, the bike fired up! In fact the clutch hasn't

slipped in five days!!!......What's up with that!!!

Another thing that I noticed was the presence of motor oil inside the

fly wheel cover along with the white grease. Is this normal?

I did not have an impact gun, so I was tightening the puller as

much as

possible with my 1/2" drive socket (and using a spanner as shown in the

manual) and then hammering quite heavily on the puller center bolt.

After my second unsuccessful attempt, I tried to put the socket back on

the puller center bolt, which I couldn't because the hammer had

mushroomed the head (file, file). This didn't seem right (duh!).

Then I remembered something about tapered arbors from decades old

machine shop. Tighten a LITTLE, then tap (not TAP or hammer), repeat as

often as necessary. So instead of torquing as much as possible and then

hammering, I did a little at a time and it came off with seemingly much

less torque on the puller center bolt and the flywheel was easily

retained from flying off by just placing my hand in front of it while I

tapped.

I suspect that initial overtorquing of the puller center bolt is

contributing to the excessive force then required to release the

flywheel from the arbor.

Not only did my procedure seem to eliminate the need to leave the bolt

in place to prevent the flywheel flying off but the flywheel center bolt

is not designed to be left in place regardless of which pulling method

you use.

Once this bolt is removed there is a large taper section at the mouth of

the bolt hole which is designed for the tapered slider that fits into

the end of the puller center bolt. Leaving the flywheel center bolt in

place causes whatever torque being applied to the puller to be applied

to the threads of the center bolt. This can't be a good thing.

Real character builder, isn't it...

Heat is the trick. I wasted 3 pullers myself. I only used 1 propane torch

but, Propane won't generate enough heat quick enough. What I did was heat,

turn, heat, turn. Don't force the puller. Took a couple days because I had

to keep running back to sears for a new puller... 3 different sears stores..

When the flywheel finally comes off, it will POP and fly a few feet. Watch

you shin bone..

Also on the puller, make sure to replace the bolts with at least grade 8 or

better. Stock puller bolts are soft and will stretch and bend. It is a bitch

of a job but you can do it..

Connect an air impact wrench that is being fed 300 psi and use

the

flywheell puller. This amount of psi can be found at a local tire

replacement company like Discount Tire in the States. It can come off

fairly simply or like mine it can be a mother.....

Use the grade 8 or better bolts like Don says, I had to use the next

grade up.. Torque down on them and make sure they are all evenly

applying pressure on the puller. Torque the main bolt on until you

can't anymore (by hand) and then tap on the end of the bolt. I had to

hit it fairly hard, but some say tap lightly. Then torque the bolt with

the air wrench til it seemingly stops and tap some more.

Torqueing/tapping then tightening is the procedure. If your lucky it

will come off and all will be right with the world. As long as your

still torqueing then your doing something so don't freak out when you

realize that you have been at it for a half hour or an hour.

The starter clutch can still be cracked and not detected from

feeling

things. Once the fly wheel is off, the baffle plate screws need to be

checked too. That is what came loose on mine the 1st time.. Caused it

to bind and crack

End of a variety of past

list posts regarding starter clutch issues/ideas.

Microfiche and Parts Sources: (links old, not

checked, most likely void)

http://www.yamaha-motor.com/products/categories/2/mcy/yamaha_motorcycles.aspx

http://www.knmotorcycles.com/

http://www.rivamotorsports.com/

http://216.37.204.203/Yamaha_OEM/YamahaMC.asp

http://www.bikebandit.com/partsbandit/Default.asp|

www.partsfish.com

www.pcwracing.net Has a gear puller

that works, plus has a 'solution' to the starter clutch issue, which I utilized.

Site/page chonology:

None of the

iowaz pages contain Vmax info/ideas after 2006.

...1996+...Most of the Zmax pages were originally uploaded to Angelfire.com

from about 1996>2002, at a time when digital photo size was small and web page

space limited. There were very few, if any, helpful Vmax pages at the

time, so the major objective of the pages was to share with other non-mechanics

various processes learned the hard way.

...2006...About 2006, a web host with unlimited storage and a better interface

available and future web work was uploaded to iowaz.com. Cycle pages were

not transfers but instead left on the free version of Angelfire. About this time more people with

much better mechanical knowledge and experience were building better pages.

....2007...By 2007, there were too many complaints and opinions coming in on some

of the Vmax pages, and especially the orange oring project that originally

started with the Zmax material, so the Vmax pages were taken offline

about this time.

...2023...Due to a requests for information a few of the old Zmax pages might be transformed

as-is from the old Angelfire material to the iowaz host. None of the

pages contain new information after the 2006 timeframe. Zmax has been gifted to another rider.

Vmax turned into

Zmax: With fork brace, head set

"fixed", frame brace, manual fan switch, Galfer green brake pads, braided

stainless steel brake and clutch lines, Speedbleeders, National Cycle Plexistar

II shield, case guards, factory sissy bar and tail piece, a few other accessory

odds and ends. Hindle 4-1 Stainless Steel Headers with a 16" Carbon Fiber

Stealth Can, K & N air filter, four 1/2" holes drilled in the air box "Y" (later

taped over), carbs left stock but needles shimmed 0.025" with five coils tied

off on the slide springs, center stand removed, Work's shocks with dual rate

springs and adjustable rider system, Works dual rate fork springs, reinstalled

Bridgestone V rated Excedra tires, T-Boost installed. PCW racing starter

clutch fix, orange-oring issue reseaches/fixed. The dyno run stock was 107+,

with mods 111+ and the curve exactly follows the stock run, no hesitations, no

weak spots. The net weight loss from center stand and stock shocks removal was

about 50lbs, which produced another net of about 6 hp, for a total gain of 10

useful hp on a massively improved handling package. Vmax was good stock, but

the frame mods, loss of weight and efficient exhaust Zmax produced the

third best bike I had owned, behind the more modern 2001FZ1 amd 2002R6. Yamaha

should have completed the basic mods needed on their stock Vmax. Zmax is

running GREAT!! bz/2006

In 2023, Iowaz' Zmax was gifted to

another rider.

Iowaz Index Page

Iowaz Index Page

Iowaz Photo Hosting Site

iowaz1@gmail.com or

iowaz@hotmail.com

Reproduction of this site

or it's contents requires consent.

Barry Zbornik

Hannibal, MO